How Yankee hood works

Installing Yankee air hood on the dryer is a better way to deal with the drying ability limited, and the practice has proved that Yankee air hood can also improve the quality and some performance indicators of paper. In particular, the loose thickness and softness of toilet paper significantly improve our newly planned Yankee air hood, the use of common new impact heat transfer theory, heat transfer coefficient up to 1500W/m2·K. Through special accounting and careful planning, we ensure that the air circulation rate in the hood is fast enough to allow the transpiration of water to be removed quickly. Blowing speed and blowing temperature are planned to match each other, the speed reflects the motor power, and the temperature corresponds to the steam flow.

Yankee hood energy saving application

Energy saving hood

Mainly for the speed of 800~1000m/min sanitary paper machine, the principle of energy-saving gas hood is similar to the principle of simple energy-saving gas hood, but because of the more sweeping waste gas, in order to make the most of this part of the heat energy, increase the heat recovery, the paper machine output of this speed is relatively large, the temperature of the hot air intake hood is relatively high, and the temperature of the hot air intake hood is relatively high. In addition to the use of condensed water and flash steam, the heater needs to use fresh full steam. The power of the hood circulating fan and exhaust fan is relatively small, the exhaust gas is also better utilized, the energy saving effect is remarkable, and the consumption of tons of paper can be controlled at about 2.2 tons of steam/tons of paper.

High efficiency high speed hot air hood

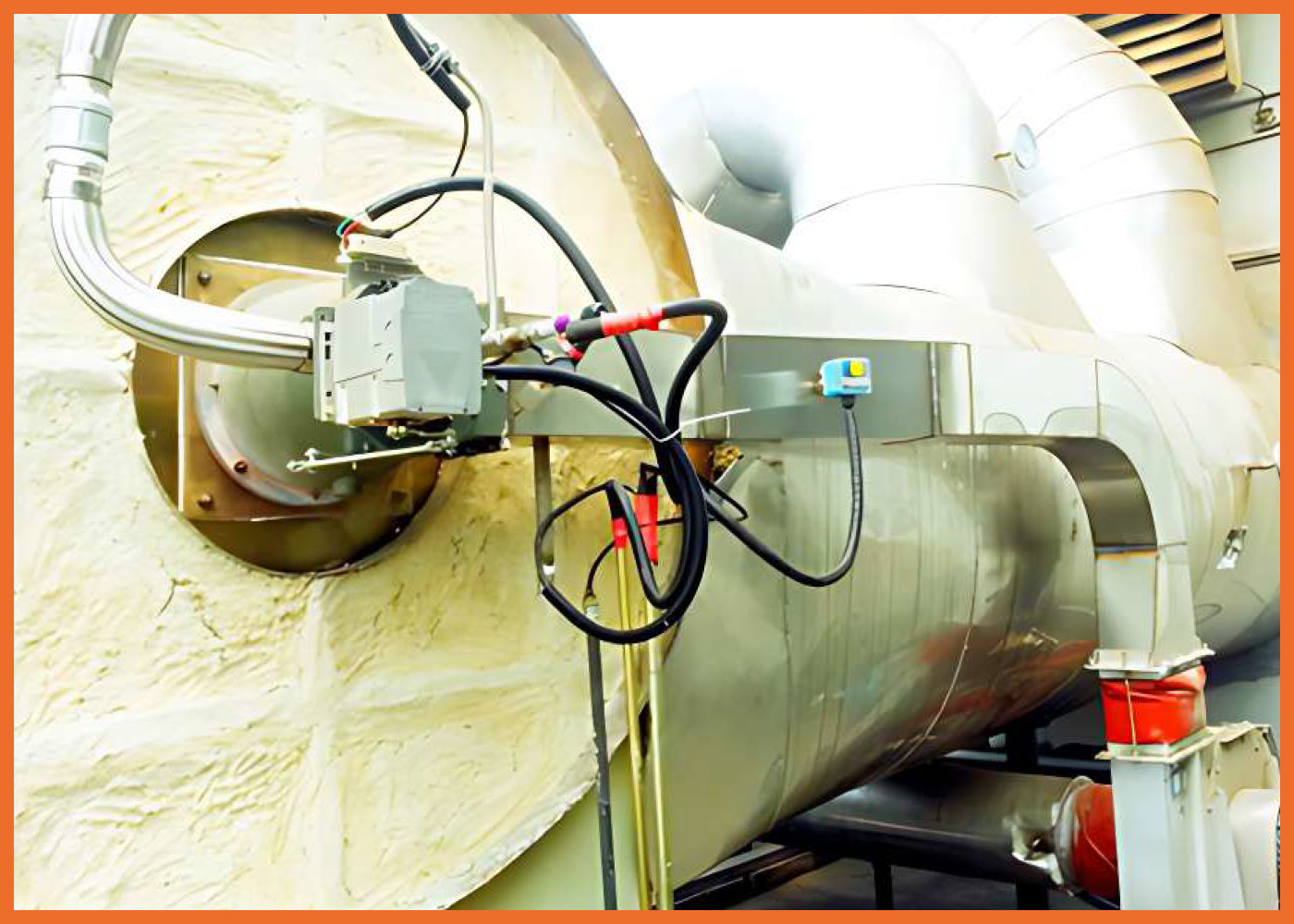

This gas hood is mainly for the sanitary paper machine with a speed of 1100-1500m/min, and the principle of planning the gas hood is to achieve the best balance of production capacity and energy consumption as far as possible. In order to adapt to the high speed and high output, the hood is planned into a double-entry and double-exit structure, the hood body is divided into dry end and wet end, each part is composed of suction chamber and expiratory chamber, the suction chamber is the external cover body, and the expiratory chamber is a blowing system composed of air supply pipes and nozzles. On the Yanke cylinder, the width of the air supply area of the heat conditioning hood is the same as that of paper. The outside of the hood is covered with heat insulation and moisture barrier to avoid heat loss and fire.

Shandong Fengxin Technology Development Co., Ltd. is a company specializing in the development, research and production of paper ventilation, drying, energy saving technology and equipment, and has achieved good results in the field of paper ventilation, drying and energy saving for many years. Fengxin closed air hood system design mainly includes the drying part closed air hood, air hood in various functions of the blower, waste heat recovery device, paper machine mesh moisture, high-speed Yanke hot air hood, all kinds of coating drying boxes, workshop ventilation system and supporting equipment.