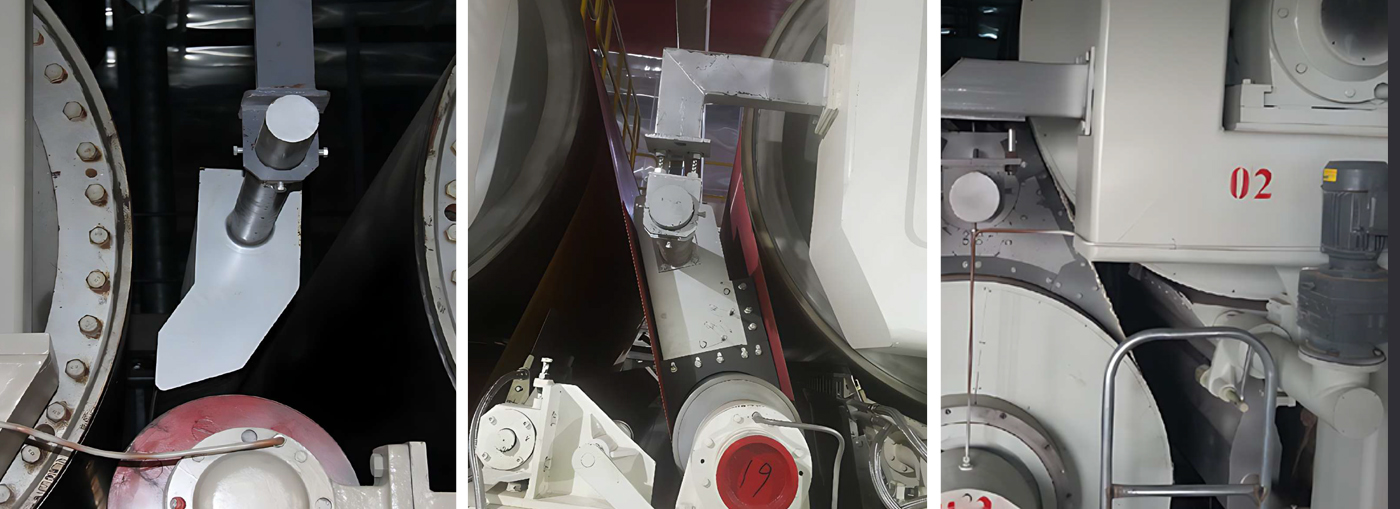

pocket blowing box

an be installed throughout the drying cadre. Good bag area ventilation and axial controllability, as well as control of increased airflow due to roll rotation, are typical features of this ventilator. When necessary, the ventilator can be fitted with adjustable sections on both sides to control the airflow distribution everywhere.

a、pocket blowing box FA

The ventilator can increase the hot air volume in the bag area to improve the drying efficiency, and can help control the transverse humidity distribution in the bag area; Balanced and consistent air volume on the longitudinal tuyere; Increased drying capacity; No dry paper edge; It has a good stabilizing effect on the running of the web. Blowing speed 30-40m/s.

b、pocket blowing box FB

Designed for pulp board paper; Large ventilation; Drying capacity is significant; The required pressure is relatively low and the energy-saving blowing speed is 20-40m/s; Perfect and smooth internal ventilation design.

paper web run blowing box

A.The vacuum roller operates the blowing box

The blowing box operated by the vacuum roller can generate negative pressure in the whole bag area at the upper part of the vacuum roller, so it can provide good running performance. In addition, the exhaust volume of the vacuum roller can be reduced, so the total energy consumption can be reduced. This concept uses specially designed blowing nozzles on both sides of the bag area to generate negative pressure between the blowing box and the dry net. This kind of blower box is not in contact with the dry net and has no mechanical seal, so it will not wear the dry net. This concept is suitable for all kinds of drying cadres running in single dry network.

The blowing box is specially developed for high-speed paper machines with a speed exceeding 1000m/min. That's right. In this high-speed paper machine, the running performance of the paper needs to be controlled in both the upward and downward running parts of the paper. This concept provides good running performance because negative pressure is formed in the whole bag area at the upper part of the grooved roll or vacuum roll. In addition, the exhaust volume of the vacuum roller is reduced, so the total energy consumption can be reduced.

①Longitudinal balanced and uniform blowing speed;

②Perfect and smooth internal ventilation design;

③thoroughly solve the paper web flutter;

④is suitable for the speed of more than 500m;

B.Single-hanging dryer running blowing box

When the paper leaves a dryer and runs to another dryer in a single dryer, the built-in pressure is generated due to the surge of airflow at high speed, so that the paper is separated from the dryer. Another undesirable effect is the adhesive force between the paper and the smooth surface of the dryer in the upper nip, and the centrifugal force generated in the lower dryer. These factors lead to the separation of the paper from the dry net, resulting in runnability problems, wrinkling or paper breakage. The blowing box is installed between the upper and lower rows of drying cylinders of the drying section of a single dry net to prevent the paper from separating from the dry net. Because this kind of blower box can generate negative pressure to eliminate the pressure in the nip between the dryer and the dry net, it can prevent the paper from separating from the dry net. In modern paper machines, a grooved down-row dryer or a drilled vacuum roller is usually used to further increase the negative pressure.

Shandong Fengxin Technology Development Co., Ltd. is a company specializing in the development, research and production of paper ventilation, drying, energy saving technology and equipment, and has achieved good results in the field of paper ventilation, drying and energy saving for many years. Fengxin closed air hood system design mainly includes the drying part closed air hood, air hood in various functions of the blower, waste heat recovery device, paper machine mesh moisture, high-speed Yanke hot air hood, all kinds of coating drying boxes, workshop ventilation system and supporting equipment.