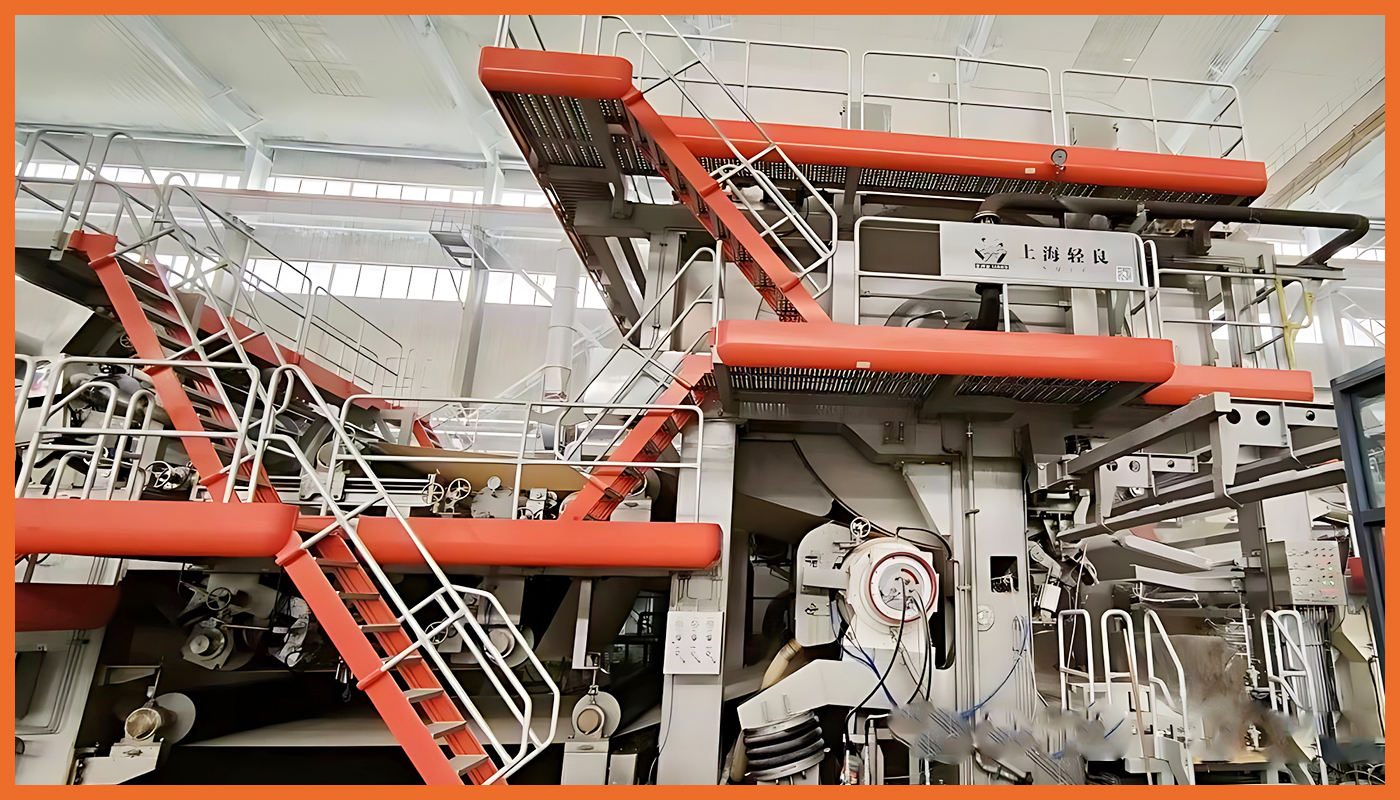

Yanke hood is a key part for the drying part of the paper machine, and the following aspects should be paid attention to when using:

Installation and commissioning phase

1. Accurate installation: Construction is strictly according to the equipment installation drawing to ensure the accurate docking and sealing of the air hood and the drying part of the paper machine. If the installation deviation occurs, the hot air will leak, affecting the drying efficiency and paper quality.

2. Check components: After installation, comprehensively check all components, including fans, heat exchangers, pipelines, etc., to ensure that the connection is tight and there is no leakage. Valves and instruments should be flexible and accurate to lay the foundation for normal operation.

3. Debugging optimization: During debugging, fine-adjust the temperature, humidity, wind speed and other parameters of the hood according to the paper varieties and production process requirements, so that it can reach the best operating state, and check the ventilation system to ensure good ventilation and timely discharge of hot and humid air and water vapor.

Routine operation phase

1. Parameter monitoring: real-time monitoring of temperature, humidity, wind speed and other parameters in the gas hood during production, timely adjustment through the control system to ensure stable drying effect of paper.

2. Maintenance equipment: regularly clean the dirt and fibers in the gas hood to prevent accumulation from affecting heat transfer and ventilation, but also regularly check and maintain fans, heat exchangers and other equipment, lubrication and replacement parts according to regulations.

3. Safe production: Because there are high-temperature components and high-speed operating equipment in the gas hood, it is necessary to ensure that the protective device is intact, the warning sign is obvious, and the development of sound safety operating procedures and strict implementation.

Down maintenance phase

1. Stop according to the rules: gradually reduce the operating parameters of the gas hood according to the operating rules, turn off and stop the related equipment in turn to prevent equipment damage and safety accidents caused by sudden shutdown.

2. Comprehensive inspection: After shutdown, the gas hood is comprehensively inspected, including the wear, corrosion and deformation of the internal components, and the faulty parts are repaired or replaced in time to prepare for the next boot.

3. Moisture-proof and rust-proof: During the shutdown period, if the gas hood is idle for a long time, it is necessary to do moisture-proof and rust-proof work, such as placing desiccant inside and coating anti-rust agents on key components.

Shandong Fengxin Technology Development Co., Ltd. is a company specializing in the development, research and production of paper ventilation, drying, energy saving technology and equipment, and has achieved good results in the field of paper ventilation, drying and energy saving for many years. Fengxin closed air hood system design mainly includes the drying part closed air hood, air hood in various functions of the blower, waste heat recovery device, paper machine mesh moisture, high-speed Yanke hot air hood, all kinds of coating drying boxes, workshop ventilation system and supporting equipment.